Multiwrapper

Simplicity, Performance and Value with OPTX™ Multiwrappers

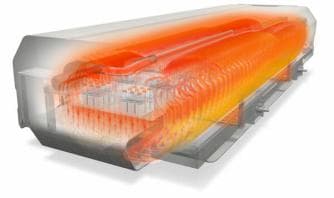

Simplified maintenance and operation provides less downtime, reduced demand on your workforce, increased productivity, optimized performance and enhanced package quality. From the first look, it’s obvious that simplicity and performance are priorities and OPTX provides more. Every element is designed to simplify operator and maintenance staff’s ability to monitor machine operation and to ergonomically access the machine when needed. Simplicity driven performance is provided through unmatched visual and physical access into the machine, clear view guard door design, reduced elevation and width. It’s a design personnel easily adopt and take ownership of. OPTX multiwrappers offer exceptional performance and the best finished package appearance and durability available.- Speed: Up to 60 cycles per minute

- Reduce packaging material costs by eliminating or minimizing corrugate use

- Film-only shrink wrap solutions for single or multiple lane production

- Pad or u-board solutions available

- Simple and repeatable changeovers

- Side mounted film stand assures proper ergonomics and adds convenience for film loading and splicing

- Flexible servo driven wrapping wand provides exceptional film control

- Shrink tunnels utilizing XACT 360™ Air Control Technology are engineered using computational fluid dynamics, providing laminar air flow and balanced heat distribution that results in optimal durability and visual appeal for every package

Eliminates soft bottle bridging and removes gaps to ensure pack pattern accuracy and continuous product flow.

- Modulated conveyor speeds control product surge and aid product flow

- Tool-less clamps and pinned lane guide adjustments for stable operation and quick, accurate changeovers

- Single clamp design at each cross member quickly locks in multiple lanes

Fast, repeatable changeover feature offers multiple enhancements.

Changeover time – significantly reduces time to less than 5 minutes (time of changeover is dependent on extent of changeover)

Repeatability – rail positions are recipe-driven and locked in place to within +/- 1/32″

Flexibility – ability to place lanes where desired as opposed to centerline or fixed side adjustments and more customer options for generating product-specific recipes

Durability – infeed rail’s holding force can withstand high product pressure

Ergonomics – minimizing manual adjustments maximizes efficiency and promotes safety in the work environment

Variable Path Metering

Innovations to our patented Slipstream™ pinless metering system incorporate variable path registration bar technology and slip sheet technology.

- Gently groups and meters products into the machine

- Dynamic variable path motion registers products with less pressure and interruption to product flow

- Provides slip sheet grouping of pack patterns for tray packing

- Run bottled, cartoned, canned and other products without the use of tampers or escapement pins

- Tool-less changeovers and preprogrammed settings increase productivity

The ergonomically designed automatic film splicer delivers precise print registration and heat splicing, reducing critical machine downtime. The easy-access side film stand enables operators to stage clear or printed film, at their convenience, while the machine is running. Staging during operation maximizes production time and minimizes the occurrence of empty film faults. Once the film is staged, no operator attention is needed for splicing. Splicing occurs automatically, providing operators considerable flexibility with work load.

This option is a great addition to a new OPTX Shrink Wrap System. Its simplicity and convenience provides an efficient work environment for the operator.

The wrapping wand uses quick change circular, elliptical or trapezoidal wand paths, depending on product size range. This results in increased film control. More benefits include a large size range and few parts to maintain.

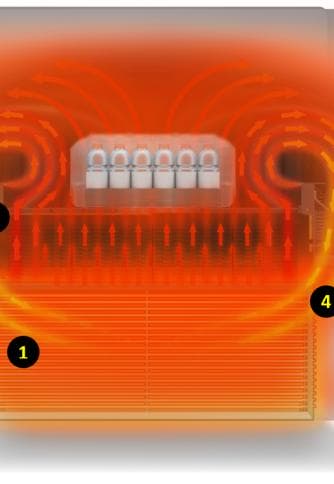

Shrink Tunnels Utilizing XACT 360 Air Control Technology – simply and consistently better packages

Unprecedented Multi-Stream Performance & Set Up Simplicity

- Heated air from within the tunnel is directed between packages to balance film shrinkage around packages

- Eliminates complex ducting between packages and related adjustments

- Patented design enables shrink tension between packages to shape bullseyes before fully separating packages

- Easy access setup key establishes optimal heat flow through conveyor for film only packaging

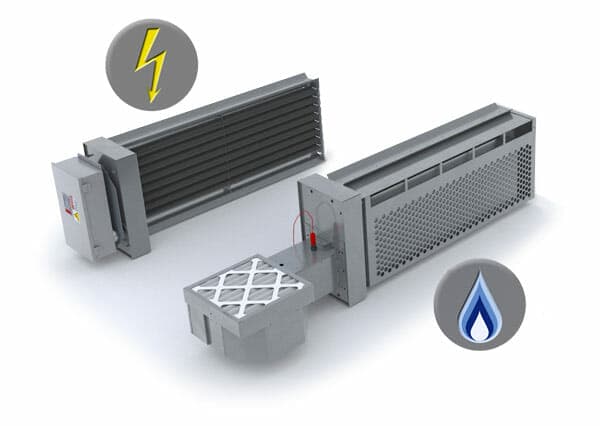

Reduce energy costs and improve production efficiency with a shorter heat-up time by using gas instead of electricity to heat the shrink wrap tunnel. Tunnel heat from 75°F to 360°F in just 20 minutes. Depending on local energy costs and the type of machine used with the gas tunnel, it is estimated that companies could cut energy costs up to 75%. Contact Douglas to calculate your estimated cost savings.

Specifications

| Speed: | Up to 60 cycles/minute |

| Product Size Range: | Minimum: 3.5″ (90 mm) x 3″ (76 mm) x 7″ (177 mm) Maximum: 11″ (279 mm) x 12″ (305 mm) x 22″ (559 mm) *Direction of Travel x Vertical x Across Machine |

| Film Thickness: | 1.5 mil to 3.5 mil printed or non-printed film |

| Film Width: | 32″ (812 mm) |

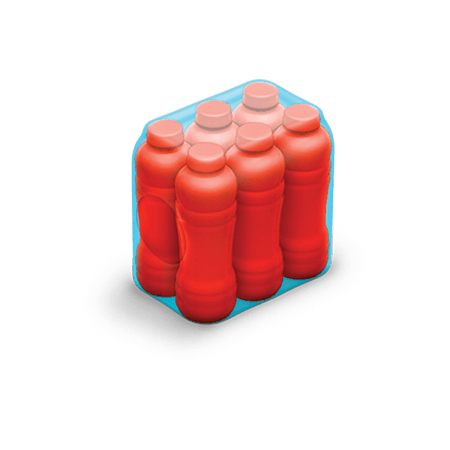

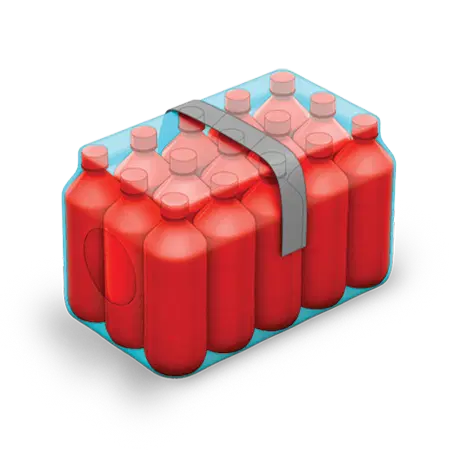

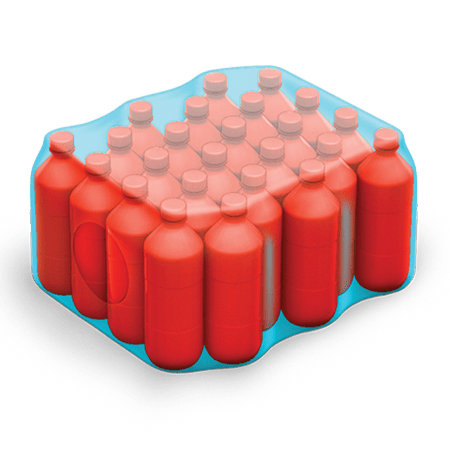

The OPTX M-60 multiwrapper easily accommodates large size ranges and pack patterns ideal for the food and beverage industries.