Top Load Case & Tray Packer

A Case & Tray Packing Workhorse

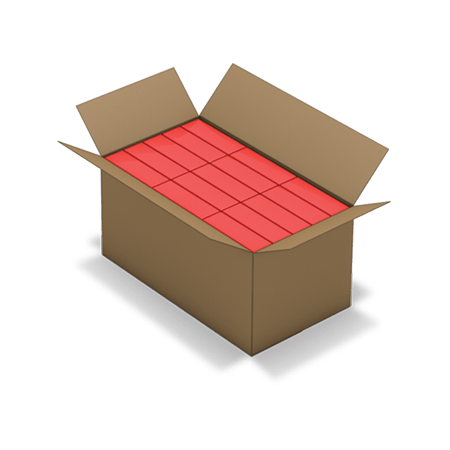

TriVex RL Series packs bags, pouches, tubs, cups, bottles and more into almost any style of top load case or tray. Its flexibility offers unique options to seamlessly erect, load and seal top load shipping cases and retail display cases and trays.

Similarly, the TriVex RLi offers product loading but with the added value of integrated case erecting, case sealing or both. Fuse the selected capabilities into one compact footprint, and control production from a single point of operation.

TriVex RL & RLi Case Packer Features

- Rates up to 25 picks per minute

- High speed, product collating systems for bags, standup pouches, cups, bottles and more

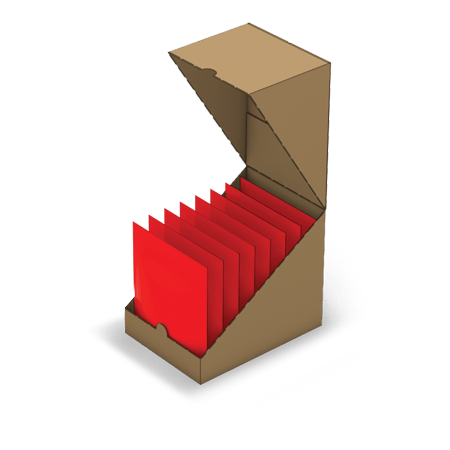

- Vertical and flat pack casing for high impact retail ready displays

- Case-tipping method packs standard shipping cases as well as single- and multi-facing retail-ready display cases and trays

- Load any type of top load case or tray

- Quick and repeatable changeovers

- Sanitary frame design and stainless steel washdown options

TriVex® RLi Additional Features

- Simple integration to new or existing case erectors and sealers

- Erects, loads and seals in one compact machine

- Modular erector and sealer configurations

- Erect, load and seal

- Erect and load only

- Load and seal only

- Optional tape or glue seal

Fast, repeatable changeover feature offers multiple enhancements.

Repeatability – rail positions are recipe-driven and locked in place to within +/- 1/32″

Flexibility – ability to place lanes where desired as opposed to centerline or fixed side adjustments and more customer options for generating product-specific recipes

Durability – infeed rail’s holding force can withstand high product pressure

Ergonomics – minimizing manual adjustments maximizes efficiency and promotes safety in the work environment

TriVex RLi is designed to erect, load and seal cases in one compact machine. With complete integration comes less product handling, less case handling and less maintenance within its compact footprint.

The TriVex RL & RLi perform efficiently and precisely to achieve the highest level of productivity. Automated infeeds collate products and position them for loading. Accurate case and flap control options ensure that cases are properly prepared for loading and that they smoothly enter and exit the loader. Customized options are added to match your case patterns and speeds.

Case Handling

Opposing vacuum cups drive the case open when corrugate slots interlock or the manufacturer’s glue joint tacks panels together.

Case Loading

TriVex’s multi-axis servo loader can be configured to meet your needs.- Vacuum

- Mechanical grippers

- Pattern rotate and load

- Product spreading or shingling

Case Closing

Case flights positively square the case. Pivoting flap folders asure that flaps fold at the score line. Tape or glue sealing is available.

Vertical Pack – Bags and pouches standing in the case

TriVex RL & RLi vertical pack solutions are used for products that need to be upright through distribution or for retail ready display packs.

Solutions include case tipping, pattern tipping, vane collation, and Delta robot feeding.

- Product control for pillow bags to standup pouches

- Products facing the major or minor panels of the case

- Excellent machine accessibility

- Simple changeover

- Small footprint

TriVex RL – Delta III uses parallel-axis robot technology. High speed multi-axis motions allow the Delta III loader to sense and pick moving product, often eliminating the need for special product handling on the infeed or the need to stage product before picking. The location and orientation of each product loaded into the case or tray is also programmable providing a high level of flexibility.

Specifications

| RL | RLi | |

|---|---|---|

| Drive: | Servo, pneumatic, and AC drives | Servo, pneumatic, AC drives, and DC magazine drive |

| Case Flights: | N/A | Lugged timing belt |

| Speed: | Standard up to 25 cases/minute (contact Douglas for applications outside range) | Standard up to 25 cases/minute (contact Douglas for applications outside range) |

| Machine Range: | Minimum: 6″ (152.4 mm) x 5″ (127 mm) x 4″ (101.6 mm) Maximum: 24″ (609.6 mm) x 16″ (406.4 mm) x 16″ (406.4 mm) * Direction of Travel x Vertical x Across Machine | Minimum: 6″ (152.4 mm) x 5″ (127 mm) x 4″ (101.6 mm) Maximum: 24″ (609.6 mm) x 16″ (406.4 mm) x 16″ (406.4 mm) * Direction of Travel x Vertical x Across Machine |

| Product Size Range: | Per project specification | Per project specification |

| Package Size Range: | Per project specification | Per project specification |

| Magazine Length: | N/A | 6′ (1.85 m) |

| Frame: | Powder coated tubular cold rolled steel | Powder coated tubular cold rolled steel |

| Adjustments: | HMI selectable recipes, threaded screws, handwheels and hand knobs with position pointers and digital scales | HMI selectable recipes, threaded screws, handwheels and hand knobs with position pointers and digital scales |

| Closing System: | N/A | Tape standard with glue option – Nordson ProBlue® or per project specification |

| Guarding: | Full length polycarbonate with extruded anodized aluminum frames | Full length polycarbonate with extruded anodized aluminum frames |

| Electrical: | Allen Bradley series programmable logic controller Allen Bradley HMI NEMA 12 wiring and enclosures NEMA 4 or 4X wiring and enclosures (optional) | Allen Bradley series programmable logic controller Allen Bradley HMI NEMA 12 wiring and enclosures NEMA 4 or 4X wiring and enclosures (optional) |

| Finish: | Gray metallic powder coat, DuPont 616 Other colors per project specification All parts in contact with product are stainless steel, anodized aluminum and plastic OEM parts are manufacturers’ standard finish | Gray metallic powder coat, DuPont 616 Other colors per project specification All parts in contact with product are stainless steel, anodized aluminum and plastic OEM parts are manufacturers’ standard finish |

| Power: | 480VAC, 50/60HZ, 3PH Other power sources available | 480VAC, 50/60HZ, 3PH Second 480VAC drop for optional glue sealing |

| Air: | One drop 90 PSI (6.2 bar) Additional drops may be required for optional features | One drop 90 PSI (6.2 bar) Additional drops may be required for optional features |

The TriVex RL & RLi servo technology delivers smooth, harmonious performance during case loading, while maintaining accurate product control with a wide variety of pack patterns.

As an automatic tray reloader, the TriVex® RL system takes the original trays in which products are delivered and reloads the trays downstream to produce the final variety pack collation. Pair the TriVex RL with a Prisma® unloader to automate product infeed.

Explore Variety Pack options »