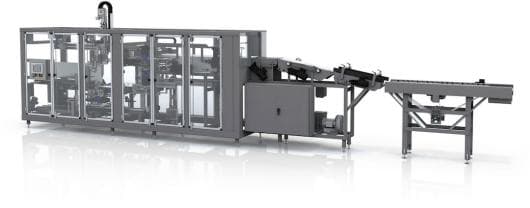

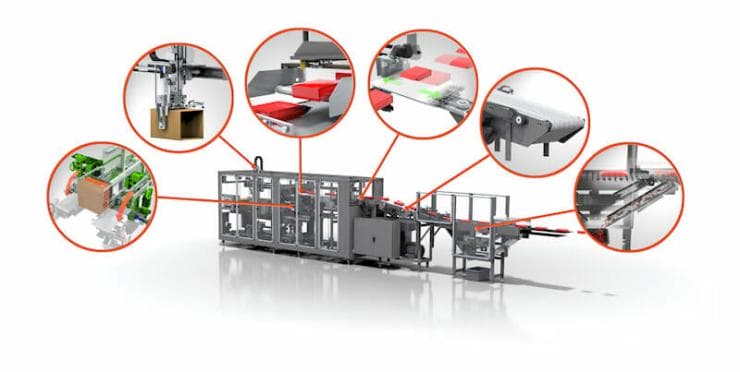

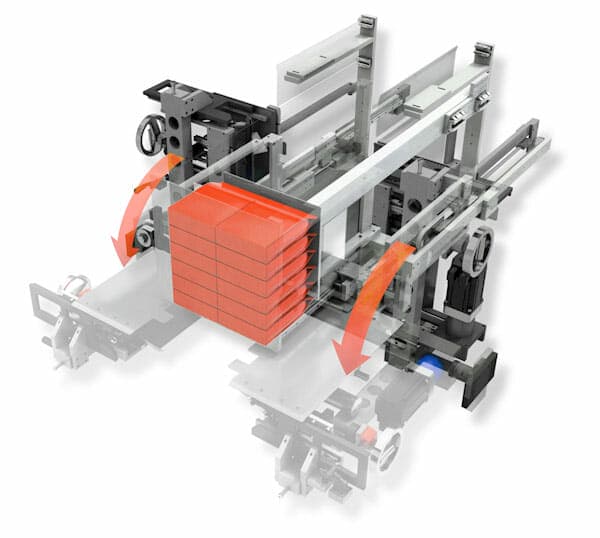

Top Load Case & Tray Packer

The Heavyweight Champ of Product Versatility

The TriVex® CLi case packer is ideal for Individual Quick Frozen (IQF) products such as non-free flowing frozen potatoes and vegetables, as well as pillow and gusseted bag product applications requiring flat and vertical bag orientations. The integrated case erector, upright and flat pack flexibility and large size range meet market demand for case packing both retail and food service bags. The convertible cassette pivots to easily reposition to horizontal or vertical mode which reduces parts and changeover time.- Speeds up to 70 bags per minute/15 cases per minute

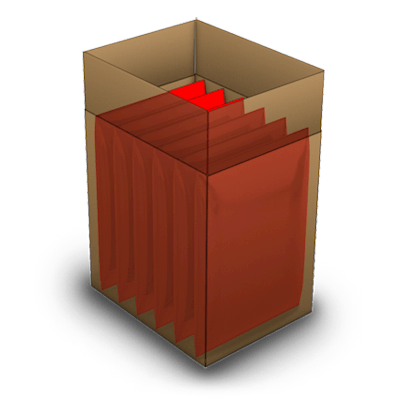

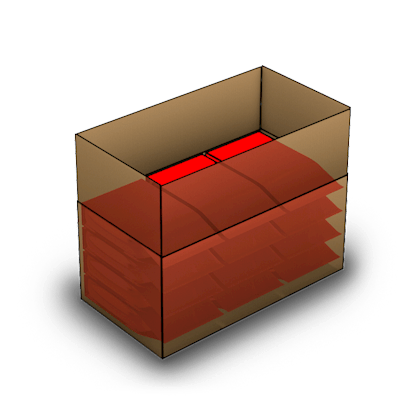

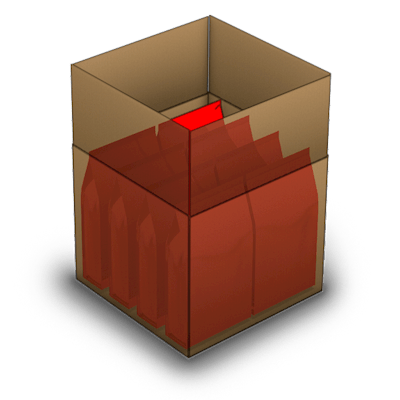

- Vertical (upright) and flat pack capabilities for both retail and food service bags

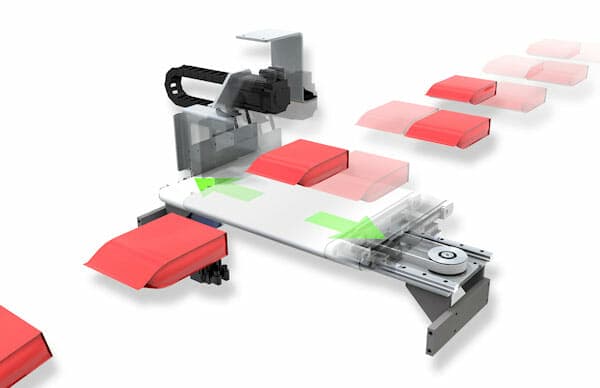

- Multi-bag collation and loading in the direction of travel (DOT), across machine (AM) and vertically manages bag conditioning and pack pattern density

- Bag conditioner with loose product eliminator and collection

- Vacuum table reduces air in perforated bags with vacuum ports adjustable to bag width

- Product Placement Conveyor (PPC) lane divider including shingling without disturbing the bag shape or pre-conditioning (AM pattern collation only)

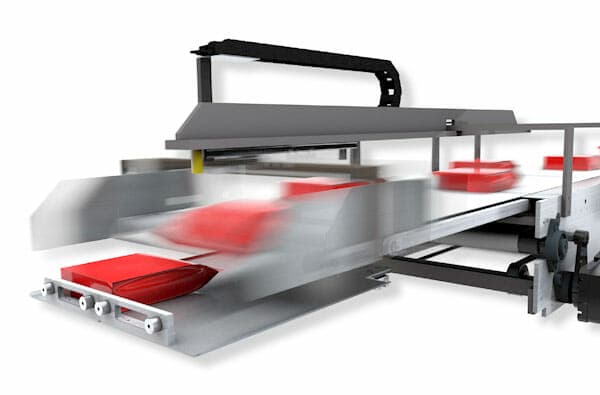

- Transpositing conveyor including shingling with minimal product disturbance (DOT pattern collation only)

- Convertible cassette pivots to easily reposition to horizontal or vertical mode which reduces parts and changeover time

- 15-minute changeover from vertical to flat pack

- Up to 40 pound pattern capability

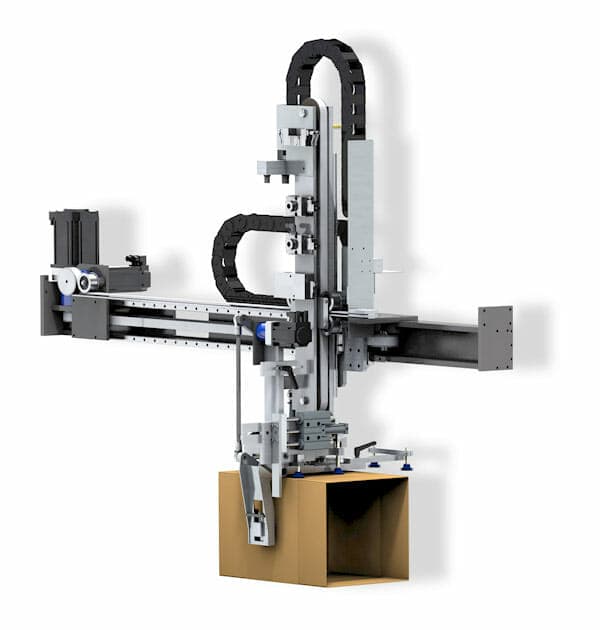

- Vertical magazine can be automatically conveyor fed

- Product maintains shape and condition (i.e. no bag distortion) throughout the packaging cycle, ensuring product quality

Integrated case erector, upright and flat pack flexibility and large size range meet market demands for case packing both retail and food service bags

Bag conditioner with loose product eliminator and collection

Vacuum table reduces air in perforated bags with vacuum ports adjustable to bag width

Product Placement Conveyor (PPC) lane divider including shingling without disturbing the bag shape or pre-conditioning (across machine pattern collation only)

Transpositing conveyor including shingling with minimal product disturbance (direction of travel pattern collation only)

Convertible cassette pivots to easily reposition to horizontal or vertical mode which reduces parts and changeover time (15-minute changeover)

Specifications

| Product Rate: | Up to 70 bags/minute |

| Case Rate: | Up to 15 cases/minute |

| Case Size Range: | Min: 7.00″ (177.8 mm) x 5.75″ (146.05 mm) x 7.00″ (177.8 mm) Max: 19.50″ (495.3 mm) x 14.50″ (368.3 mm) x 19.50″ (495.3 mm) * Direction of Travel x Vertical x Across Machine |

| Product Type: | Individual Quick Frozen (IQF) products such as non-free flowing frozen potatoes and vegetables, as well as pillow and gusseted bag product applications requiring flat and vertical bag orientations |

| Pack Pattern Orientation: | Vertical and flat pack solutions |

| Case Type: | Corrugated |

| Pattern Collation: | Vertical bag orientation = Direction of Travel & Across Machine Flat bag orientation = Direction of Travel, Vertical & Across Machine |

| Payload Weight: | 40 pound pack pattern |