Shrink Wrappers

Exceptional Package Quality in a Compact Shrink Wrapper

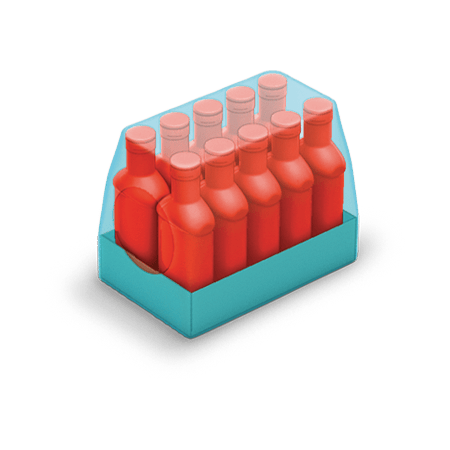

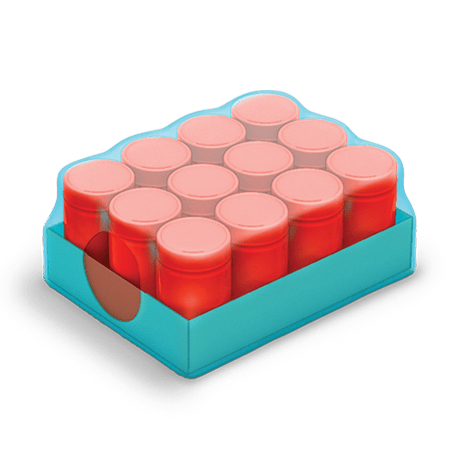

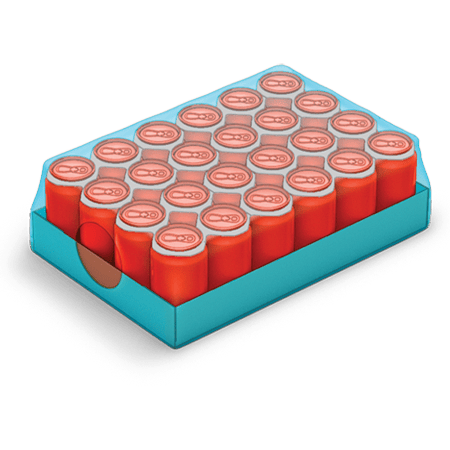

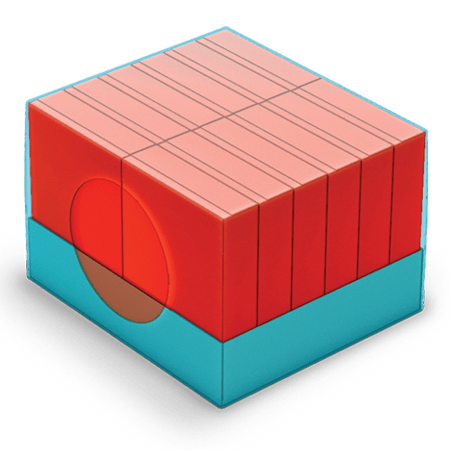

The VS Series shrink wrappers offer a compact, economical shrink wrap solution designed to interface with existing tray packers, including the Douglas Invex® and Axiom™ at speeds up to 40 trays per minute. Using single film roll technology, costly maintenance problems associated with conventional cutting and sealing technologies are eliminated. The optional print-registered film control gives you the ability to further enhance your package appearance on the store shelf. Combined with Douglas’ proprietary heat tunnel technology, the VS series shrink wrappers ensure your brand is always presented with quality and pride. Small footprint, big advantages … the VS Series sets a new standard for compact shrink wrap performance.- Speeds:

- VS-25: up to 25 cycles per minute

- VS-40: up to 40 cycles per minute

- Clear or printed film wrapping of trayed products

- Available as a stand-alone unit or integrated with an Axiom or Invex case/tray packer

- Simple and repeatable changeovers

- Single roll side film stand for easy film loading and splicing

- Flexible servo-driven wrapping wand provides exceptional film control

The wrapping wand uses quick change circular, elliptical or trapezoidal wand paths, depending on product size range. This results in increased film control. More benefits include a large size range, the ability to accept randomly spaced products and few parts to maintain.

The Douglas heat tunnel is designed with the aesthetics of your product in mind. Unprecedented heat and airflow management ensures minimal graphic distortion, consistent bull’s-eyes and a tighter, more durable wrap.

Specifications

| Speed: | VS-25: up to 25 cycles/minute VS-40: up to 40 cycles/minute |

| Product Size Range: | Minimum: 6″ (152 mm) x 3″ (76 mm) x 6″ (152 mm) Maximum: 17″ (432 mm) x 12″ (305 mm) x 22″ (559 mm) * Direction of Travel x Vertical x Across Machine |

| Film Thickness: | 1.5 mil to 3.5 mil printed or non-printed film |

| Film Width: | Minimum: 10” (254 mm) Maximum: 27″ (686 mm) |

The VS Series easily accommodate large size ranges and pack patterns ideal for the food and beverage industries.