Shrink Wrappers

OPTX™ Shrink Wrappers Give You More … Performance, Package Quality and Simplified Operation

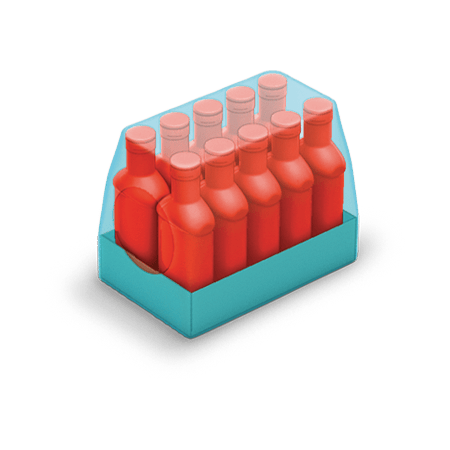

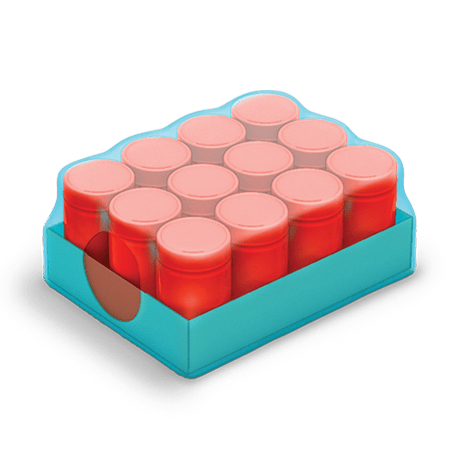

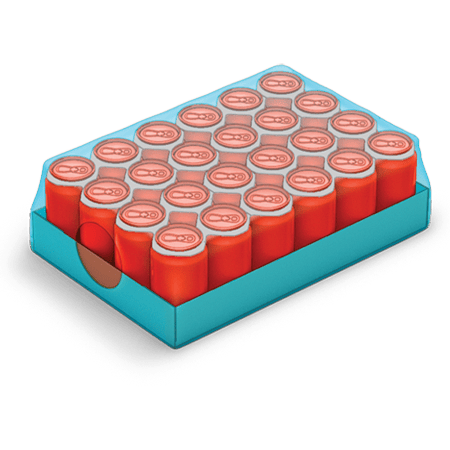

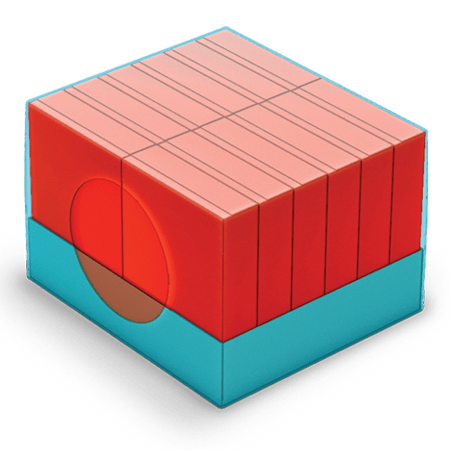

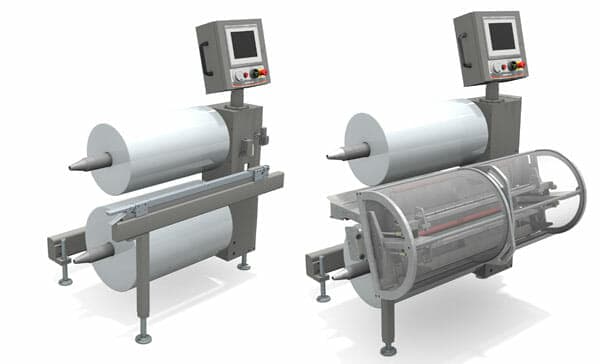

OPTX shrink wrappers excel with flexibility, performance and package quality. Simplicity is the backbone of this platform and the productivity it provides. OPTX offers a full spectrum of innovative features that maximize speed and easily accommodate large size ranges ideal for the food and beverage industries. What does this mean for you? Less downtime and increased productivity for the machine and your operations personnel.- Speeds:

- OPTX S-30: up to 30 cycles per minute

- OPTX S-60: up to 60 cycles per minute

- Available as a stand-alone unit or integrated with a tray packer

- Simple and repeatable changeovers

- Clear or printed film wrapping of trayed product

- Single or dual spindle side film stands available for easy film loading and splicing

- Flexible servo driven wrapping wand provides exceptional film control

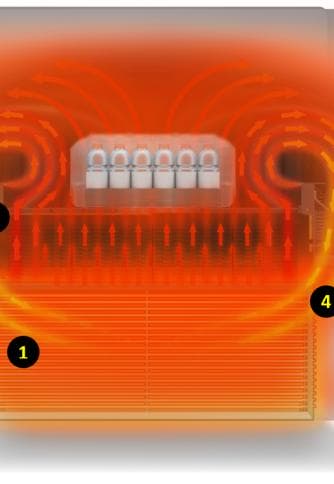

- Shrink tunnels utilizing XACT 360™ Air Control Technology are engineered using computational fluid dynamics, providing laminar air flow and balanced heat distribution that results in optimal durability and visual appeal for every package

Film roller design counteracts wrinkles and overlapping

induced by variations in film, improving cutting efficiency

and package quality.

The single nip roller and vacuum belt film delivery combine with a servo driven cutting knife to provide efficient operation.

The ergonomically designed automatic film splicer delivers precise print registration and heat splicing, reducing critical machine downtime. The easy-access side film stand enables operators to stage clear or printed film, at their convenience, while the machine is running. Staging during operation maximizes production time and minimizes the occurrence of empty film faults. Once the film is staged, no operator attention is needed for splicing. Splicing occurs automatically, providing operators considerable flexibility with work load.

More uptime, more productivity … this option is a great addition to a new OPTX Shrink Wrap System. Its simplicity and convenience provides an efficient work environment for the operator.

The wrapping wand uses quick change circular, elliptical or trapezoidal wand paths, depending on product size range. This results in increased film control. More benefits include a large size range, the ability to accept randomly spaced products and few parts to maintain.

Shrink Tunnels Utilizing XACT 360 Air Control Technology – simply and consistently better packages

1 – Heated air is delivered through conveyor chain with laminar flow to bond the lap seal and surround each package 360°

2 – With simple recipe selection, exclusive “air knives” automatically adjust to inject targeted air precisely where needed for specific pack characteristics

3 – Gentle laminar airflow improves package consistency by reducing wrinkle-inducing turbulence in the tunnel

4 – Recycling of cooled air reduces heater loads and minimizes heat loss, while tunnel outer shroud temperatures remain cool to the touch

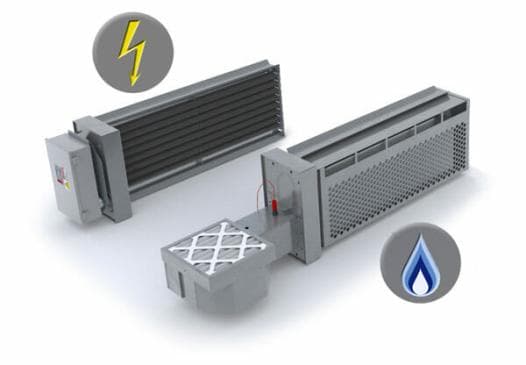

Reduce energy costs and improve production efficiency with a shorter heat-up time by using gas instead of electricity to heat the shrink wrap tunnel. Tunnel heat from 75°F to 360°F in just 20 minutes. Depending on local energy costs and the type of machine used with the gas tunnel, it is estimated that companies could cut energy costs up to 75%. Contact Douglas to calculate your estimated cost savings.

Specifications

| Speed: | OPTX S-30: up to 30 cycles/minute OPTX S-60: up to 60 cycles/minute |

| Product Size Range: | Minimum: 5″ (127 mm) x 3″ (76 mm) x 9.5″ (241 mm) Maximum: 14″ (355 mm) x 12″ (305mm) x 22″ (558 mm) *Direction of Travel x Vertical x Across Machine |

| Film Thickness: | 1.5 mil to 3.5 mil printed or non-printed film |

| Film Width: | 32″ (810 mm) |

OPTX S-30 & S-60 shrink wrappers easily accommodate large size ranges ideal for the food and beverage industries.