Multiwrapper

Simplicity, Performance and Value with OPTX™ Multiwrap Shrink Bundlers

OPTX multiwrappers offer exceptional performance and the best finished package appearance and durability available. Simplicity is the backbone of this platform, making it a shrink bundler that simply performs. OPTX offers a full spectrum of innovative features that maximize speed and easily accommodate large size ranges and pack patterns ideal for the food and beverage industries. What does this mean for you? Simplified maintenance and operation provides less downtime, reduced demand on your workforce, increased productivity, optimized performance and enhanced package quality.- Speeds:

- OPTX M-80: up to 80 cycles per minute

- OPTX M-105: up to 105 cycles per minute

- Reduce packaging material costs by eliminating or minimizing corrugate use

- Film-only shrink wrap solutions for single or multiple lane production

- Pad or u-board solutions available

- Simple and repeatable changeovers

- Side mounted film stand assures proper ergonomics and adds convenience for film loading and splicing

- Flexible servo driven wrapping wand provides exceptional film control

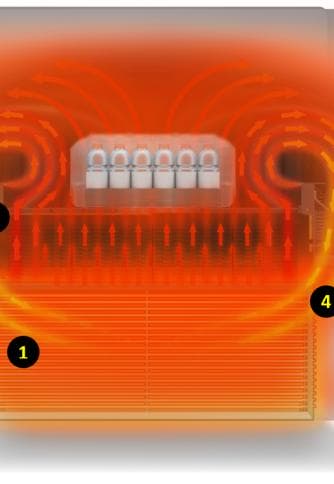

- Shrink tunnels utilizing XACT 360™ Air Control Technology are engineered using computational fluid dynamics, providing laminar air flow and balanced heat distribution that results in optimal durability and visual appeal for every package

- Mass flow or individual lane infeed solutions to suit round and square shaped products.

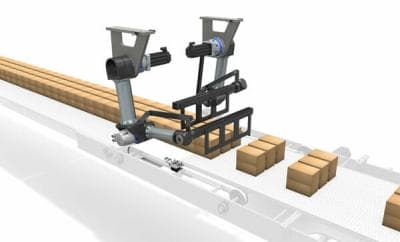

- Smartrak infeeds optimize product flow, controlling product surge and lane population. Its tool-less and pinned lane adjustment method provides stable operation and quick, accurate changeovers.

- Optional SmartSelect® provides automated lane position changeover. Infinite adjustment positions capable of being set for mass flow or laned products.

- Product optimized lane guide design and vibratory options address product bridging/binding.

Fast, repeatable changeover feature offers multiple enhancements.

Changeover time – significantly reduces time to less than 5 minutes (time of changeover is dependent on extent of changeover)

Repeatability – rail positions are recipe-driven and locked in place to within +/- 1/32″

Flexibility – ability to place lanes where desired as opposed to centerline or fixed side adjustments and more customer options for generating product-specific recipes

Durability – infeed rail’s holding force can withstand high product pressure

Ergonomics – minimizing manual adjustments maximizes efficiency and promotes safety in the work environment

OPTX provides the simplicity and control that operators and maintenance personnel desire.

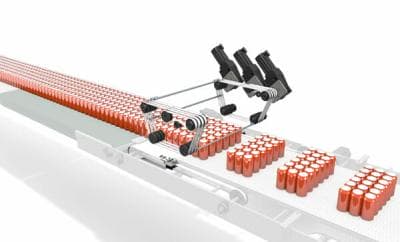

- To increase flexibility, OPTX metering systems handle round containers and square shaped products including cartons and bundles with simple changeover. Solutions include variable path robotic metering, with its innovative simplicity over conventional pin metering systems, and Slipstream™ pinless metering system.

- Optimizing product stability and size range flexibility, full width conveyors span the grouping section.

- For efficient transfer of product groups to sweep bars, acceleration of product groupings is controlled.

- Unmatched visual and physical access is provided for changeover and routine operation, a result of having no roller chains under the product, no individual lane transport chains and adjustments, and overhead supported lane guides requiring no disassembly.

Variable Path Metering

Intuitive operation physically registers leading edge of product groups and controls group separation from incoming flow.

- Recipe setting of product group length and controlled separation

- Dual overhead pin bars register and release product groups of round products

- A simple change to straight bars and recipe control of a variable position transfer point positively meters groups of cartons, bundles and square cornered containers

- Changeover is simplified with open access to 2 registration bars, unobstructed lane guide adjustments, and recipe selection

Slipstream Pinless Metering

Incorporating slip sheet methodology and technologies managing incoming line pressures, Slipstream Pinless metering manages incoming line pressures for highly accurate product registration and more.

- Provides slip sheet grouping of pack patterns for tray packing

- Run bottles, cartons, cans and more without the use of tampers or escapement pins

- Tool-free changeovers and preprogrammed settings increase productivity

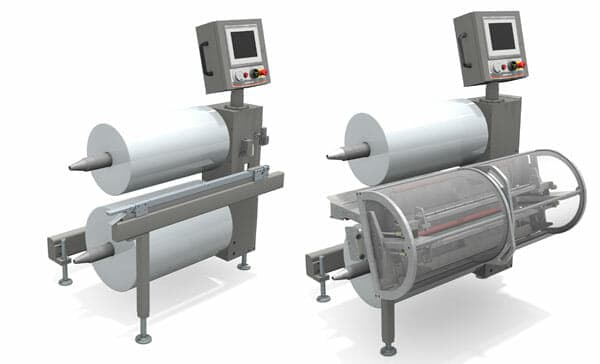

Film handling and wrapping

Reliability and simplicity that operations staff favor. Operating tolerance and package quality are the focus of OPTX film handling, with performance enhancing features integrated into every element.

- Ergonomic side mounted film stand and an available automatic film splicer enhance safety and productivity

- Film roller design counter-acts wrinkles and overlapping induced by variations in film, improving cutting efficiency and package quality

- Our patented film slit-perforation system enables shrink film tension between packages to control inside bullseye formation when running multi-stream production

- Film cutting efficiency is designed in delivering operation tolerance and simplicity

- Reduced occurrence of uncut film and film transfer issues through the cutter

- Film cutting tension assured by proprietary single nip roller and vacuum table designs with edge-to-edge film control; reduces missed cuts due to tension loss that can occur in designs with dual nip rollers

- Vacuum table provides positive film transfer and control, eliminating the second nip roller and related setup and film transfer issues

- High-speed cutting motion provides consistency, tolerance against film variations, and optimized full-width cutting

- Simplified maintenance and access

- Access for film threading and knife maintenance provided by the single nip roller design

- Sensitivities of setup between dual nip rollers is eliminated

- Automatic drive belt tracking extends belt life

- Self-tensioning vacuum/film-delivery belts

- Reduced occurrence of uncut film and film transfer issues through the cutter

- Precise film delivery and wrapping profiles set the stage for package quality

The ergonomically designed automatic film splicer delivers precise print registration and heat splicing, reducing critical machine downtime. The easy-access side film stand enables operators to stage clear or printed film, at their convenience, while the machine is running. Staging during operation maximizes production time and minimizes the occurrence of empty film faults. Once the film is staged, no operator attention is needed for splicing. Splicing occurs automatically, providing operators considerable flexibility with work load.

This option is a great addition to a new OPTX Shrink Wrap System. Its simplicity and convenience provides an efficient work environment for the operator.

The wrapping wand uses quick change circular, elliptical or trapezoidal wand paths, depending on product size range. This results in increased film control. More benefits include a large size range and few parts to maintain.

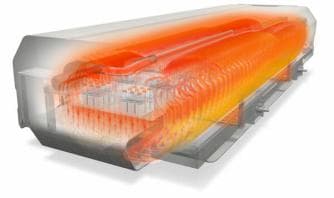

Shrink Tunnels Utilizing XACT 360 Air Control Technology – simply and consistently better packages

Unprecedented Multi-Stream Performance & Set Up Simplicity

- Heated air from within the tunnel is directed between packages to balance film shrinkage around packages

- Eliminates complex ducting between packages and related adjustments

- Patented design enables shrink tension between packages to shape bullseyes before fully separating packages

- Easy access setup key establishes optimal heat flow through conveyor for film only packaging

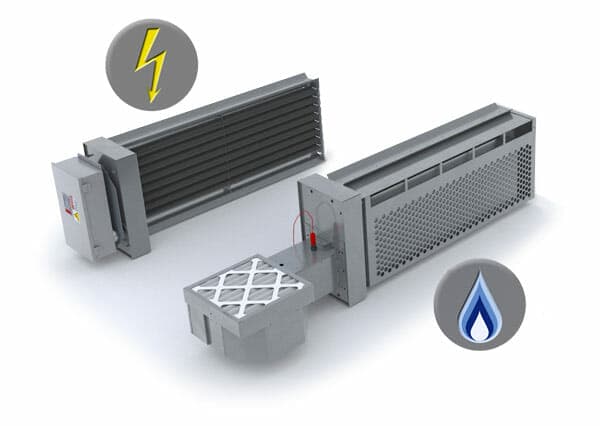

Reduce energy costs and improve production efficiency with a shorter heat-up time by using gas instead of electricity to heat the shrink wrap tunnel. Tunnel heat from 75°F to 360°F in just 20 minutes. Depending on local energy costs and the type of machine used with the gas tunnel, it is estimated that companies could cut energy costs up to 75%. Contact Douglas to calculate your estimated cost savings.

Specifications

| Speed: | OPTX M-80: Up to 80 cycles/minute OPTX M-105: Up to 105 cycles/minute |

| Product Size Range: | Minimum: 3.5″ (90 mm) x 3″ (76 mm) x 7″ (177 mm) Maximum OPTX M-80: 11″ (279 mm) x 12″ (305 mm) x 22″ (559 mm) Maximum OPTX M-105: 8″ (203 mm) x 12″ (305 mm) x 22″ (559 mm) *Direction of Travel x Vertical x Across Machine |

| Film Thickness: | 1.5 mil to 3.5 mil printed or non-printed film |

| Film Width: | 32″ (812 mm) |

OPTX M-80 & M-105 multiwrappers easily accommodate large size ranges and pack patterns ideal for the food and beverage industries.