Continuous Motion Case & Tray Packer

Streamlined Performance with Straight Through Product Flow

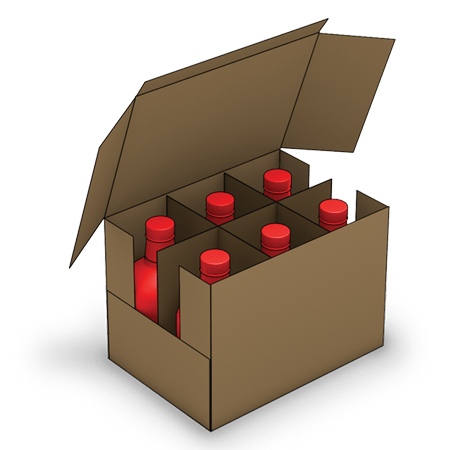

Using dual paddle metering to directly load product onto the case or tray blank minimizes unnecessary components to increase production efficiency. Servo functions reliably and accurately pack cartons, bottles, cans, jars, jugs and more using innovative infeed technology and high speed horizontal case loading methods with precise product control.- Speeds up to 55 cases or trays per minute

- Gentle servo driven product handling

- Inline direct loading into case or tray

- Precise flap gluing, folding and compression – no flight chain camming

- Continuous motion case squaring and sealing produces squared cases at high speeds

- Simple and repeatable changeovers

- Large size range

- Walk-in frame design

Metering

Metering

The Axiom™ DL offers inline product flow and gentle delivery into the case or tray. Its compact footprint is able to reach speeds up to 55 cases or trays per minute.

Flap folding and compression – Flap folding from the sides of the machine provides more accurate glue application and compression than systems with cammed flight chains.

A variety of advanced infeed solutions are offered to optimize performance for specific product types while maintaining gentle product handling to ensure highest package integrity. Some commonly used systems include:

Servo Lane Mergers and Dividers – Perfect for applications where any shape or sized product cannot be flood or mass fed. A fixed number of products are smoothly fed to metering systems, where balanced product lanes are required.

Recirculating Conveyors – A complete recirculating loop system that controls product population and reduces line pressure as products are distributed into lanes.

Recirculating Conveyor

Recirculating Conveyor

Fast, repeatable changeover feature offers multiple enhancements.

Changeover time – significantly reduces time to less than 5 minutes (time of changeover is dependent on extent of changeover)

Repeatability – rail positions are recipe-driven and locked in place to within +/- 1/32″

Flexibility – ability to place lanes where desired as opposed to centerline or fixed side adjustments and more customer options for generating product-specific recipes

Durability – infeed rail’s holding force can withstand high product pressure

Ergonomics – minimizing manual adjustments maximizes efficiency and promotes safety in the work environment

Eliminates soft bottle bridging and removes gaps to ensure pack pattern accuracy and continuous product flow.

- Modulated conveyor speeds control product surge and aid product flow

- Tool-less clamps and pinned lane guide adjustments for stable operation and quick, accurate changeovers

- Single clamp design at each cross member quickly locks in multiple lanes

Specifications

Contact Douglas for detailed specifications.