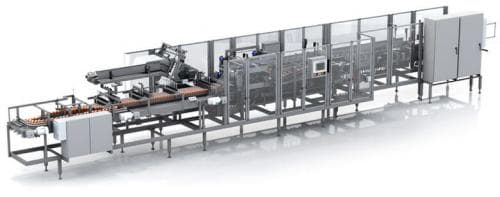

Multipacker | Cartoner

Maximum Reliability and Efficiency Regardless of Environment

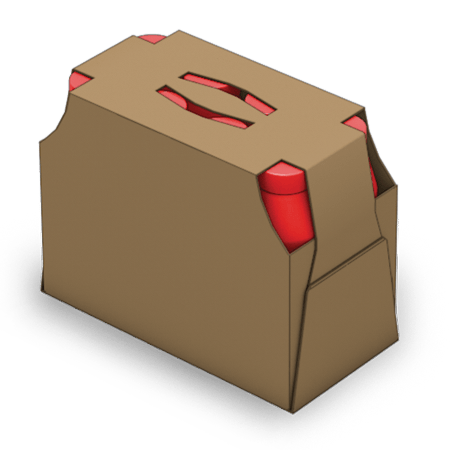

Your beverage cartoning operations require durable, high-speed machinery. Douglas Spectrum™ Multipackers are continuous motion cartoners built tough for less downtime, high efficiencies, and low operating costs in the most demanding environments. The Spectrum uses electronic motion control to multipack soft drink, brewery, dairy or nutraceutical products.- Speeds to 2,400 cans or 1,400 bottles per minute

- 4-24 single tier packs

- Flood style infeed keeps your line running

- Air-assisted and positive placement carton setup adapts to varying carton style

- Seating wheel loading gently transfers product

- Live closure and static plows ensure consistent cartons

- Cycle stop flap closing prevents unsealed cartons from exiting

- Open frame designed for efficient sanitation

Fast, repeatable changeover feature offers multiple enhancements.

Changeover time – significantly reduces time to less than 5 minutes (time of changeover is dependent on extent of changeover)

Repeatability – rail positions are recipe-driven and locked in place to within +/- 1/32″

Flexibility – ability to place lanes where desired as opposed to centerline or fixed side adjustments and more customer options for generating product-specific recipes

Durability – infeed rail’s holding force can withstand high product pressure

Ergonomics – minimizing manual adjustments maximizes efficiency and promotes safety in the work environment

Specifications

| Drive: | Servo motors |

| Pitch: | Application dependent |

| Flight Chains: | Application dependent |

| Speed: | Up to 2,400 cans or 1,400 bottles/minute |

| Product Size Range: | Per project specification |

| Package Size Range: | Per project specification |

| Magazine Capacity: | 6′ (1828.8 mm) standard, shorter or longer capacities optional |

| Frame: | Tubular or bar stock powder coated carbon steel |

| Legs: | Threaded |

| Adjustments: | Threaded screws, handwheel and hand knobs with position pointers and scales Digital scales, phase adjustments and tool-less packages (application dependent) optional |

| Infeeds: | Flood style |

| Carton Setup/Feeder: | Rotary placer with vacuum or air assisted carton setup |

| Carton Positioning: | Traveling flights |

| Glue System: | Nordson ProBlue® or per project specification |

| Carton Closing: | Plow type with dynamic flap folding and controlled stop |

| Compression: | Timing belt drive or static compression |

| Guarding: | Polycarbonate guarding, other guard packages per project specification (optional) |

| Electrical: | Allen Bradley programmable logic controller or per project specification Touch screen operator interface panel NEMA 12 wiring and enclosures NEMA 4 or 4X wiring and enclosures optional Stackable warning lights (optional) |

| Finish: | Continuous weld tubular cold-rolled steel with powder-coated cold rolled steel bolt-on frame members Grey metallic, DuPont 616 All parts in contact with product are stainless steel, anodized aluminum or food grade plastic OEM parts are per manufacturers’ standard finish |

| Power: | 230/480V, 50/60HZ, 3PH Single drop Other power sources available |

| Air: | 80-100 PSI (5.5-6.9 bar) Single drop |

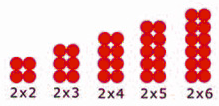

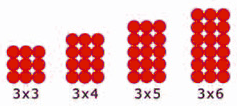

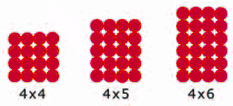

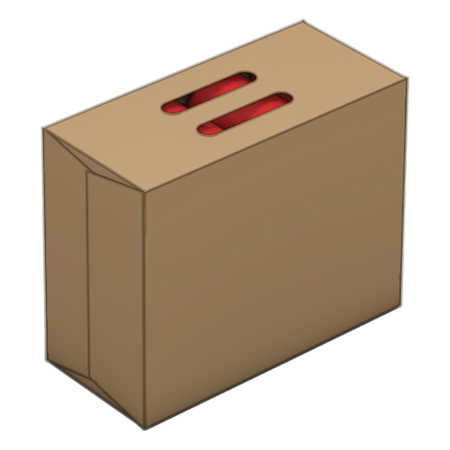

The Spectrum Multipacker easily accommodates large size ranges and pack patterns for food and beverage cartoning.

For mid- to high-speed automated cartoning, the Spectrum CM cartoner can function as a standalone platform with manual infeed. Combine it with a Prisma® unloader to automate product infeeding as well as a TriVex® tray reloader to automate downstream tray loading.

Explore Variety Pack options »